RT students at Boise State University will get the chance to experience some of the world’s most cutting edge technology this semester.

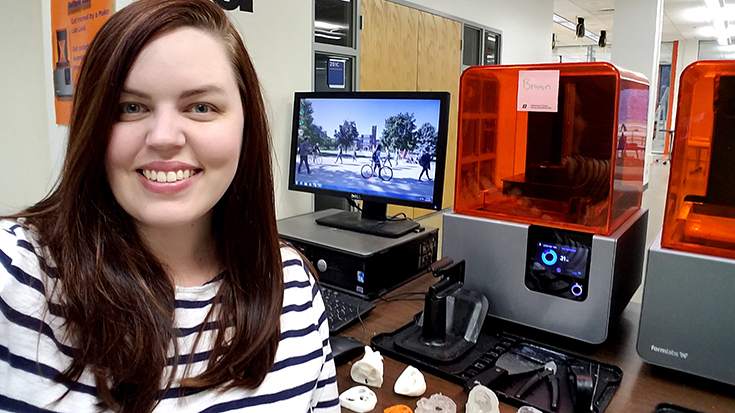

Thanks to Samantha Davis, MS, RRT-NPS, AE-C, they’ll be using the university’s 3D printing capabilities to print neonatal cardiac defects.

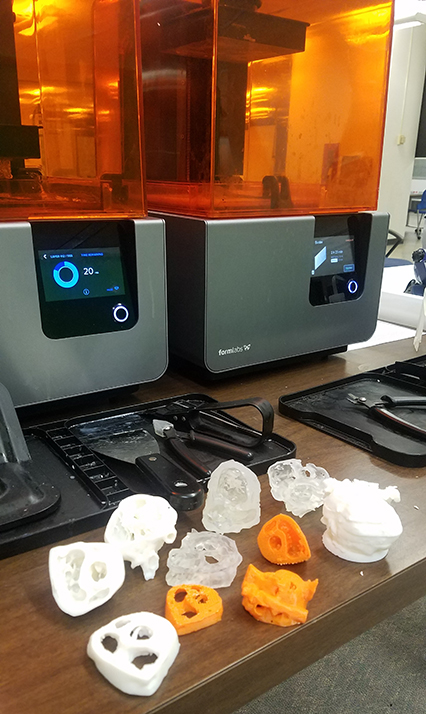

“Each group will print a normal heart in addition to their assigned defect,” Davis said. “Each of the hearts are cut into 3-4 slices so the defects within the heart can be easily seen.”

Students in the neonatal/pediatric respiratory course will have several weeks to test and print their models before presenting them to the entire class.

A happy coincidence

How did Davis come up with the idea of using 3D printing with her RT students? The AARC member admits it was “pure coincidence.” She was in the campus library one day and decided to stop by a place that had always piqued her interest.

Called the “MakerLab,” it offers students and professors the chance to work with their hands and their imaginations to create something using new technologies like 3D printing.

“I was introduced to the concept of ‘making’ and got to see all of the great resources available on campus for our students and faculty — all free of charge,” Davis said.

In addition to 3D printing, the lab includes resources for creating videos or podcasts and equipment that can be used to create digital media for patient education.

“It’s a combination of problem solving, practical skill, and creativity,” Davis said. “Making allows you to take the great ideas you have and bring them to life where you can touch them, test them, and make them even better.”

Endless possibilities

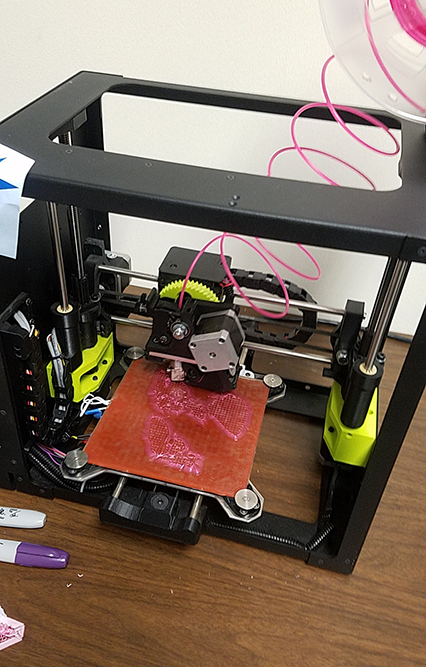

3D printing in particular is a technology that can be used to make anything from toys to complicated body parts like the hearts that will be constructed by the RT students. Simply put, the equipment allows users to create three dimensional images by adding individual layers of material until the object is completed.

“The material is fed into the machine, melted, then deposited onto the plate where the object is created layer by layer,” says Davis.

The National Institutes of Health (NIH) hosts a free online program called 3D Print Exchange that features thousands of ready-to-print files ranging from DNA sequences to body parts. Davis believes the technology holds great potential, not only for medical education, but also for clinical treatment.

“The possibilities are endless,” Davis said. “Outside of the NIH 3D Print Exchange, software exists that can transform various digital media such as CT scans, MRI, etc. into a 3D printing file. We can scan a patient and recreate their exact anatomy quickly, cost effectively, and with extreme accuracy and detail.”

Those models could be invaluable in complex cases. For example, a 3D replica of an anatomical defect that captures the intricate detail of the nerves and vasculature could be created to guide a surgery.

“Imagine how useful that could be in preparing surgeons for a challenging surgical case before they even pick up a scalpel,” Davis said.

Labor of love

The RT students who will take part in the 3D printing exercise will receive a quick training session in the MakerLab before dividing into small groups to create their normal hearts and heart defects.

“Defects are being assigned because, at the time of printing, this will be new information to the students,” Davis said. “They are printing the hearts in advance to use as a supplement to their learning when the time comes.”

She says she spent much of the fall semester working with Amy Vecchione, head of emerging technology and experiential learning at Boise State, to get up to speed on the new technology and perfect the files the class will be using.

“This project has certainly been a labor of love,” Davis said.

Seeking the “ah-ha” moment

It’s also the first time 3D printing will be used by the respiratory program, although other departments on campus have used it before, with great success.

“Elsewhere on campus, students who had access to 3D printed models scored significantly higher when tested on that content compared to students who did not have access to the models,” Davis said.

She believes the biggest benefit for her students, however, will be the ability 3D printing gives them to better understand a difficult concept.

“Countless studies have shown us that engagement, application, and critical thinking are all significantly higher when active-learning strategies are used,” Davis said. “In the past, students have had to learn about neonatal heart defects through reading, discussion, and computer animation.”

Creating 3D printed hearts in the MakerLab will give her students a physical model of each of the main heart defects. They’ll get to see and touch them while engaging in classroom discussion about the challenges each defect presents in terms of oxygenation and ventilation.

“If just one of my students has an ‘ah-ha’ moment from working with their 3D printed heart, then all of my hours spent preparing for this project have been worth it,” Davis said.